In recent years, the organic agriculture movement has gained significant traction among consumers, farmers, and policymakers alike. With an increasing demand for sustainable farming practices and organic food, the production of organic fertilizers has become an industry of paramount importance. Large-scale organic fertilizer manufacturing is not just an environmentally conscious decision but also a response to a growing market need. In this blog post, we’ll delve into the world of organic fertilizer production on a grand scale, exploring its benefits, challenges, and the future it holds for agriculture.

The Organic Advantage

Organic fertilizers are derived from natural sources such as plant, animal, and mineral matter. Unlike their synthetic counterparts, these fertilizers enrich the soil with organic matter, nitrogen, phosphorus and potassium, promoting soil health, increasing water retention, and encouraging biodiversity. The advantages are clear:

– Sustainable Practices: Organic fertilizers contribute to sustainable agricultural cycles, avoiding the depletion of soil nutrients and reducing chemical runoff into water bodies.

– Enhanced Soil Structure:The use of organic materials improves soil structure, leading to better root growth and enhanced nutrient uptake by plants.

– Long-term Fertility:Organic fertilizers release nutrients slowly, providing a long-term supply of nourishment to crops.

Scope of Large-Scale Production

Transitioning from small-scale composting to large-scale organic fertilizer manufacturing requires significant investment and strategic planning. Here’s what such a scale of operation typically encompasses:

– Sourcing Raw Materials:Large-scale production of organic fertilizer relies on extensive sources of organic waste, such as crop residues, livestock manure, food waste, and industrial organic by-products.

– Advanced Composting Techniques:Employing advanced composting methods like windrow composting, in-vessel composting, or aerated static pile composting can handle substantial quantities of organic waste efficiently.

– Quality Control:Consistent product quality is vital. This involves regular testing for nutrient content, pathogen levels, and the presence of any contaminants.

– Packaging and Distribution:Efficient packaging solutions are required to handle large volumes, along with a robust distribution network to reach diverse markets.

Investment and Costs

To set up a large-scale organic fertilizer manufacturing plant, the financial outlay can be considerable. Key cost factors include:

– Facility and Infrastructure:This includes the cost of land, construction, and the setup of composting systems and storage facilities.

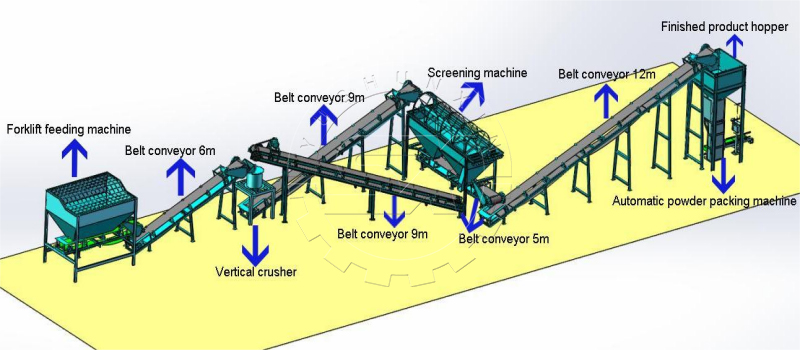

– Machinery and Equipment: Investment in heavy-duty equipment like compost turners, shredders, mixers, granulators, and packaging machines is necessary. Click here to learn more.

– Regulatory Compliance:Ensuring adherence to environmental regulations and obtaining necessary certifications can incur additional costs.

– Research and Development:Staying competitive may require ongoing R&D to improve product effectiveness and to develop new fertilizer formulations.

Overcoming Challenges

Expanding into large-scale organic fertilizer production is not without its challenges:

– Supply Chain Management:Establishing reliable sourcing channels for organic waste and managing logistics is crucial.

– Odor Control and Environmental Concerns: Large-scale composting operations must address odor control and ensure minimal environmental impact.

– Market Competition:Competing against established chemical fertilizers and other organic products requires strategic marketing and brand positioning.

The Future Holds Promise

Despite the challenges, the future for large-scale organic fertilizer manufacturing looks bright, driven by factors such as:

– Policy Support:Many governments now promote organic farming through incentives and subsidies.

– Market Demand:The organic food market is witnessing robust growth, with consumers increasingly willing to pay a premium for sustainable produce.

– Technological Innovation:Advances in composting technologies and automation are making large-scale production more viable and efficient.

Conclusion

As the world tilts toward sustainable farming, large-scale organic fertilizer manufacturing stands out as a crucial industry for the future of agriculture. It represents an intersection of ecological responsibility and economic opportunity, offering a way to support the planet’s health while tapping into a lucrative market. Though not without its challenges, the industry’s trajectory suggests that organic fertilizer production will continue to scale up, fueled by innovation, policy support, and a collective commitment to sustainable agriculture. If you are interested in the ptoject, you can visit https://www.fertilizerbusinessplan.com/how-to-make-organic-fertilizer-in-a-large-scale/