В цепочке создания стоимости производства удобрений гранулирование является ключевым этапом. Это не просто процесс физического формования, а основная технология, определяющая рыночную конкурентоспособность продукта, эффективность использования питательных веществ и рентабельность производства. Переход от рассыпчатого порошка к однородным, прочным гранулам — это успешное гранулирование, которое может напрямую привести к качественному скачку вашей продукции.

Четыре ключевые проблемы традиционных порошковых удобрений. Сталкиваетесь ли вы с ними?

1. Серьёзная проблема пыли: образование пыли при производстве и использовании приводит к потере действующих питательных веществ (до 5-15%), загрязнению окружающей среды, вреду для здоровья рабочих и несоответствию ужесточающимся экологическим нормам.

2. Неудовлетворительные физические свойства: гигроскопичность, слёживаемость, плохая сыпучесть, что вызывает проблемы с хранением, затрудняет фасовку и серьёзно влияет на равномерность механического внесения.

3. Низкая рыночная стоимость: грубая форма порошкового удобрения, непривлекательный товарный вид, что обычно позволяет продавать его только как низкосортное сырьё или полуфабрикат, сильно сжимая маржу прибыли.

4. Низкая эффективность использования питателей: порошковые удобрения после внесения легко разносятся ветром, смываются водой или быстро разлагаются, что затрудняет достижение эффекта медленного/контролируемого высвобождения и снижает коэффициент использования удобрений.

Специализированное оборудование для гранулирования удобрений: решение, превращающее проблемы в прибыль

Инвестиции в подходящее гранулирующее оборудование означают инвестиции в будущее вашего продукта. Оно позволяет:

Создавать превосходный продукт: производить гранулы однородного размера, высокой прочности, округлые и гладкие, повышая класс товара и удовлетворённость клиентов.

Обеспечить эффективное производство: автоматизированный, непрерывный процесс гранулирования значительно увеличивает производительность, снижая удельное энергопотребление и трудозатраты.

Расширить пространство для прибыли: гранулированные удобрения можно продавать как готовый товар, их добавленная стоимость заметно выше, чем у порошкового сырья, и их легче брендировать.

Способствовать научному удобрению: технология гранулирования позволяет точно производить сложные/смешанные удобрения (BB-удобрения), удобрения с медленным высвобождением, органо-минеральные комплексы и другие высококлассные удобрения по индивидуальному заказу, отвечая потребностям современного сельского хозяйства.

Руководство по выбору технологий и оборудования для гранулирования удобрений

Не существует «универсального» оборудования, есть только решение, наиболее подходящее для вашей рецептуры и задач. Вот анализ основных типов:

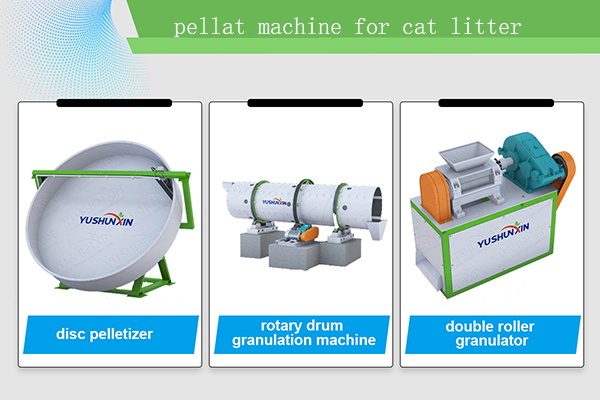

1. Барабанный гранулятор / Гранулятор с тарельчатым диском (тарельчатый гранулятор)

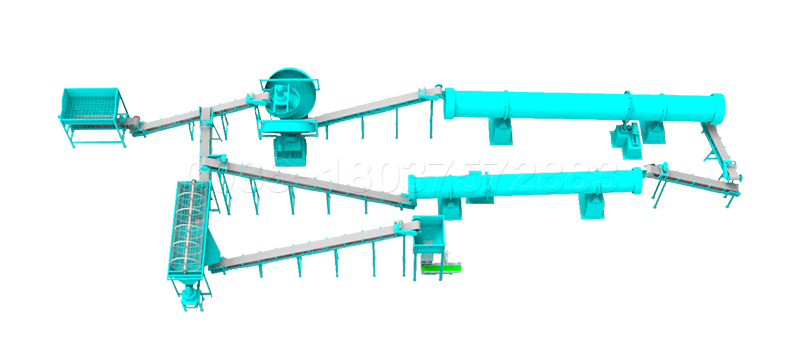

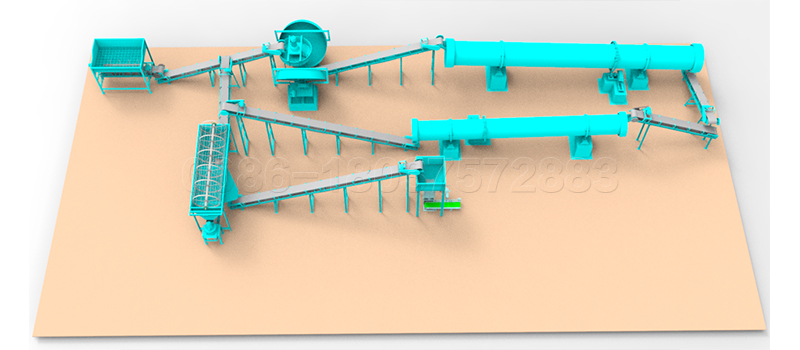

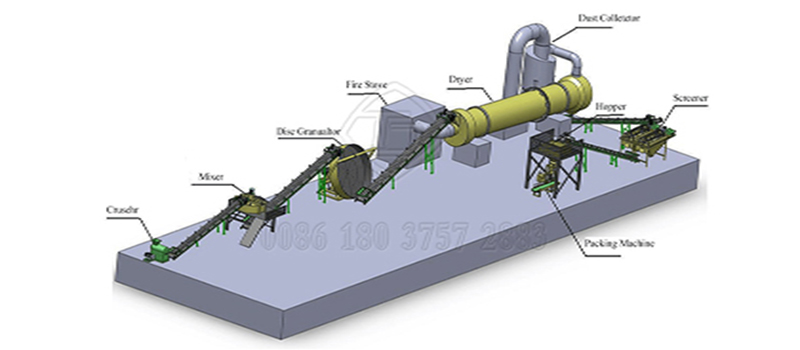

Принцип: За счёт вращения барабана или наклонного диска увлажнённые порошковые материалы слипаются в шарики при перекатывании, постепенно увеличиваясь и уплотняясь.

Ключевые преимущества: Отличная сферичность гранул, возможность регулировки размера (обычно 2-10 мм), высокий выход годных гранул, наглядность процесса.

Применение: Агломерационное гранулирование для комплексных, органических, биоорганических, смешанных удобрений. Идеально подходит для высокопроизводительных линий, где важен внешний вид гранул.

2. Двухвалковый экструзионный гранулятор (пресс-гранулятор, сухой способ)

Принцип: Без добавления жидких связующих. Сухой порошок под высоким давлениемно спрессовывается двумя валками в плотные пластины, которые затем дробятся и просеиваются для получения правильных гранул.

Ключевые преимущества: Отсутствие стадии сушки, значительная экономия энергии; высокая чистота продукта, без химических изменений; чрезвычайно высокая прочность гранул, низкая вероятность разрушения; особенно подходит для термочувствительных материалов.

Применение: Гранулирование хлористого калия, сульфата калия, аммиачной селитры с кальцием, неорганических микроудобрений, некоторых комплексных удобрений.

3. Высокоскоростной роторно-лопастной смеситель-гранулятор (мокрый способ)

Принцип: В смесителе высокоскоростные вращающиеся лопасти интенсивно сдвигают и смешивают порошок со связующим, образуя однородные мелкие гранулы.

Ключевые преимущества: Высокая скорость гранулообразования, плотные гранулы, совмещение смешивания и гранулирования в одном аппарате, подходит для материалов со сложной рецептурой.

Применение: Кормовые добавки, удобрения для тонкого химического синтеза, гранулированные пестициды, специальные удобрения, требующие высокой степени однородности смеси.

Примеры успеха: от центра затрат к двигателю прибыли

Пример А: Трансформация и повышение эффективности завода по производству органических удобрений

Проблема: Использование устаревшего оборудования, сильное слёживание продукта, много пыли, низкая цена и затоваривание.

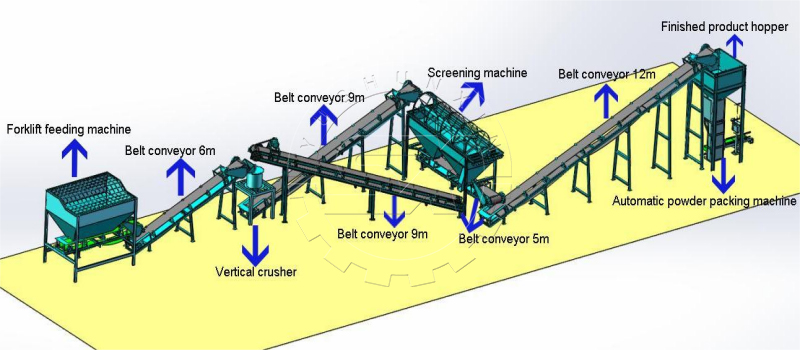

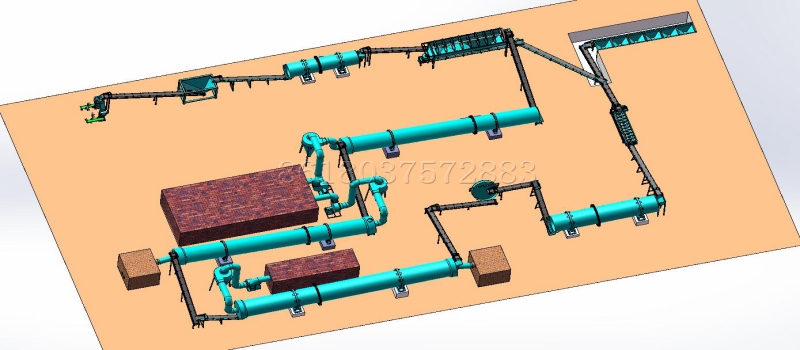

Решение: Мы установили для них интегрированную линию: «предварительное измельчение + смешивание + барабанное гранулирование + сушка/охлаждение».

Результат: Производство высококачественных органических гранул однородного размера и высокой прочности на раздавливание. Цена продукта выросла на 40%, спрос превышает предложение, инвестиции в оборудование окупились в тот же год.

Пример Б: Модернизация линии по производству комплексных удобрений

Проблема: Высокое энергопотребление существующей технологии, продукт легко разрушался в пыль, много жалоб от клиентов.

Решение: Внедрение новой технологии парового барабанного гранулирования для замены части традиционного процесса, оптимизация рецептуры и параметров оборудования.

Результат: Выход годных гранул увеличился с 88% до более чем 95%, улучшилась растворимость гранул, эффективность удобрения возросла, что значительно усилило конкурентоспособность на рынке.

Как выбрать идеальное гранулирующее оборудование? — Метод принятия решений в 4 шага

1. Определите цели: Какие удобрения вы планируете производить (NPK, органические, специальные)? Какая целевая производительность? Каковы конкретные требования к форме, размеру и прочности гранул?

2. Проанализируйте сырьё: Предоставьте образцы сырья (порошок) для бесплатного лабораторного анализа для определения состава, размера частиц, липкости, термостабильности и т.д. Это основа для научного выбора.

3. Оцените технологию: Наши инженеры, учитывая свойства сырья и требования к продукту, порекомендуют наиболее экономически эффективный технологический маршрут гранулирования и основное оборудование.

4. Учитывайте общую картину: Оценивайте не только цену отдельной машины, но и рациональность проектирования всей линии, степень автоматизации, энергопотребление, послепродажную поддержку и возможность расширения в будущем.

Мы предлагаем не просто оборудование, а комплексное решение для повышения стоимости

Как поставщик комплексных решений для производства удобрений, мы стремимся предоставить вам:

Бесплатные испытания сырья и проектирование технологии: Проверка процесса гранулирования с вашим сырьём в нашем испытательном центре до покупки.

Индивидуальные проекты «под ключ»: Полная ответственность от проектирования и изготовления оборудования до монтажа, пусконаладки и обучения.

Постоянная техническая поддержка и поставка запчастей: Обеспечение долгосрочной стабильной работы вашей линии и поддержание технологического лидерства.

Действуйте сейчас, начните свой путь к повышению стоимости удобрений!

Планируете ли вы новый проект или хотите модернизировать существующую линию, у нас есть богатый опыт и примеры успеха. Попрощайтесь с пылью и неэффективностью, шагните в новую эру гранулированного, высокоценного производства удобрений. Давайте вместе превратим ваши идеи в удобрения, лидирующие на рынке! Для получения более подробной информации, пожалуйста, посетите:https://www.liniyaudobreniy.com/granulyator/

And you can consider our organic compost machine, when you

And you can consider our organic compost machine, when you

The crush process and grind process are more important process in

The crush process and grind process are more important process in

In the end, if you want to make organic fertilizer and you don’t know how to do it, you can visit my website:

In the end, if you want to make organic fertilizer and you don’t know how to do it, you can visit my website: