Cat litter, an indispensable product for cat owners worldwide, undergoes a meticulous production process to ensure its effectiveness in odor control and moisture absorption. From the preparation of raw materials to the final packaging stage, each step plays a crucial role in delivering a high-quality product. In this comprehensive guide, our company SX delve into the intricacies of cat litter production, exploring each stage in detail. Click

1. Preparation of Raw Materials

The cat litter production line begins with the careful selection and preparation of raw materials. Primary ingredients such as clay minerals, silica gel, and natural fibers are sourced from reputable suppliers. These raw materials undergo rigorous quality checks to ensure they meet the required standards for cat litter production. Additionally, any additives, such as odor neutralizers or antimicrobial agents, are procured and prepared according to specific formulations.

2. Mixing Materials and Additives

Once the raw materials are assembled, they undergo a series of pretreatment processes to optimize their properties for cat litter production. This may involve washing to remove impurities, drying to achieve the desired moisture content, and grinding to achieve the appropriate particle size. Each raw material is treated with precision to enhance its absorbency and clumping ability, ensuring superior performance in the final product.

3. Crushing Materials

In the crushing stage, raw materials are further processed to achieve the desired consistency and particle size. This step is critical for enhancing the absorbency and texture of the cat litter. Specialized machinery such as crushers and pulverizers are employed to break down the raw materials into uniform particles, ready for the next stage of production.

4. Sifting Materials

Following the crushing stage, the materials undergo a sifting process to remove any oversized or undersized particles. This ensures uniformity in particle size, essential for consistent performance in absorbing moisture and controlling odor. Fertilizer sifting equipment is utilized to achieve precise particle size distribution, resulting in high-quality cat litter with optimal clumping properties.

5. Mixing Materials and Additives

Once the raw materials are prepared and sifted, they are carefully blended to create the final cat litter formula. Additives such as fragrance enhancers, antimicrobial agents, and moisture-absorbing compounds are precisely measured and added to the mixture according to specific formulations. The mixing process is closely monitored to ensure thorough dispersion of additives, resulting in a homogenous blend ready for granulation.

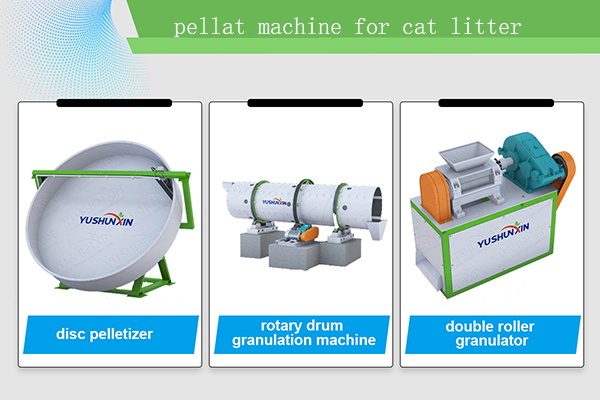

6. Granulating Cat Litter

Granulation is a crucial stage in cat litter production, where the mixed materials are formed into granules of uniform size and shape. This is typically achieved using a granulator or pelletizer, which compacts the mixture under controlled pressure to create consistent granules. The granulation process enhances the clumping ability and absorbency of the cat litter, ensuring easy scooping and effective odor control.

7. Drying, Cooling, and Packing

The final stage of cat litter production involves drying, cooling, and packing the granules for distribution. The granules are carefully dried to remove any remaining moisture, ensuring optimal performance and shelf stability. After drying, the cat litter is cooled to room temperature before being packed into bags or containers of various sizes. Each package is sealed to preserve freshness and prevent moisture ingress, ready to be shipped to retailers and cat owners worldwide.

In conclusion, the production of cat litter is a meticulous process that involves careful selection, preparation, and processing of raw materials to create a high-quality product. From the initial stages of raw material preparation to the final packaging phase, each step is essential in ensuring the effectiveness and reliability of cat litter for maintaining a clean and hygienic environment for cats and their owners. Click https://www.fertilizerequipmentprice.com/cat-litter-production-line/